Zinc

CEl Torcal de Antequera Nature Park Visitors' Centre, Málaga. Natural zinc roof (caption) Appearance

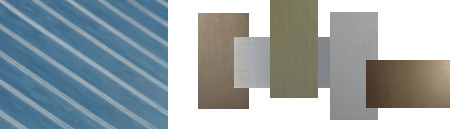

The natural colour of zinc is light metallic silver. Exposed to the elements, this colour loses its shine gradually whilst darkening a little over time to finish in a bluish-grey colour. The colour of the metal develops more slowly on facades than on roofs but in the end both attain the same tone, taking approximately 2 years and 1 year respectively to reach this mature state. UpOther finishesThere are several very elegant finishes, mainly in different tones of grey.

The most popular tones are pre-patinated grey, which has light satin grey tones. It is similar to the colour that natural zinc takes after exposure to the elements for several months. This colour is stable on facades and roofs, barely changing tone. It is a colour that looks light and modern, used more on facades than on roofs given the extra time required for a facade to become patinated. The range continues with a very dark pre-patinated, anthracite, satin tone. It combines very well with slate and other natural materials. A new tone has been added to these two traditional colours. This refers to pre-patinated tones with shades of blue, red and green. These colours keep the metallic texture of zinc, providing a subtle yet distinctive look to the work. Quinta Metálica was the first installer in Spain to work with the bluish zinc from this new range.

Houses in Astilleros, Santander. Blue pigmented zinc roof (caption) For more information on the different finishes available in zinc, please take a look at the other files on our metals. Other characteristicsZinc has several qualities that make it particularly appropriate for covering roofs and facades:

However, we have to pay close attention to the following aspects:

Zinc can be used in the following systems of ours:

The following materials can be used a direct support with a ventilation membrane:

Pine decking can be used (treated in special autoclave), either 18 or 22mm with 5 to 10mm imprints between the planks without needing the ventilation membrane. The following separating sheets/ventilation membranes can be used

Marino Lejarreta Cycling Stadium, Berriz. Pre-patinated zinc roof (caption)

Regional Animal Health Laboratory, Villaquilambre. Pre-patinated zinc facade (caption)

Request for information

For technical consultancy on your project, please contact Quinta Metálica and we will be happy to help you.

Up Documents |

© Quinta Metálica · c. Juan Bautista Escudero 273· Córdoba· 14014 Córdoba

Tel.: 91 896 1898· arquitectura@quintametalica.com

Legal Advice

Ficha Zinc (507.35 kB)

Ficha Zinc (507.35 kB)